Hemlock siding is quickly becoming a ‘go to’ softwood siding for builders, designers, and homeowners. And why not? Hemlock siding is naturally beautiful real wood, with the warm look of red cedar siding. Better yet, hemlock siding is more readily available and more affordable than cedar. Hemlock siding is available kiln dried or as thermally modified siding. Which is better?

Thermally modified Hemlock (Hem-Fir) has a beautiful range of warm natural color tones and graining

Thermally modified Hemlock (Hem-Fir) has a beautiful range of warm natural color tones and graining

What is Thermally Modified Hemlock?

The unique process that thermally modifies hemlock uses a vacuum kiln. It's a game changer. The vacuum kiln raises the pressure, so less heat is required to ‘cook’ the sugars out of the wood. The process uses less energy and creates a clearly superior thermally modified finished product.

When softwoods like Pine, Larch, Spruce, Hemlock or Hem Fir are thermally modified, it generally makes the wood harder, more rot resistant, and more stable (less movement) than the original wood. On the downside, it usually makes the thermally modified wood a little more brittle than the original wood. However, thermally modified hemlock performs better in many ways.

RELATED: Thermally Modified Hem Fir Wood siding gallery

Compare KD Hemlock Siding to Thermally Modified Hemlock Siding

Strength Comparisons

Thermally modified Hemlock is stronger than standard hemlock. Scientific testing confirms that Therma Hemlock is 107% more difficult to break than kiln dried hemlock (Modulus of Rupture test). Thermally modified is also 102% less brittle than the original wood (Modulus of Elasticity test).

The winner (by a head): Thermally Modified Hemlock

Hardness

Janka hardness testing measures the amount of force it will take to embed a .444" steel ball halfway into a piece of wood. Thermally modified hemlock is almost exactly as hard as non-modified hemlock (Janka hardness test). It takes 622 lbs. of pressure to put a .444” diameter steel ball halfway into a piece of thermally modified hemlock.

The winner: Tie

RELATED: Thermally Modified Hem Fir Wood Siding information

Dimensional Stability

When people talk about the ‘stability’ of wood, they are referring to dimensional stability. All woods will expand and contract in different moisture conditions, especially in outdoor weather. Dimensional stability testing measures precisely how much a wood will expand (swelling) and contract (shrinkage) when water is added or taken away. Thermally modified woods are almost always much more stable than their non-modified counterparts.

Stable siding is a major benefit in both wood rainscreen siding designs and installations as wells as T&G wood siding projects.

Thermally modified hemlock is ‘off the charts’ more stable than kiln dried hemlock. To begin with, KD Hemlock exhibits very little expansion and contraction. But when hemlock is thermally modified in a vacuum kiln, the results are utterly amazing.

Vertical grain thermally modified hemlock siding shrinks 1.5% as it dries. Vertical grain thermally modified hemlock siding swells up to 1.8% as it picks up moisture. Wow, that is highly stable.

- This means that a 1 x 6 nominal piece of vertical grain thermally modified hemlock siding will expand or contract less than 1/8” over the face of the board.

- A 1x8 nominal piece of vertical grain thermally modified hemlock will contract less than 1/8” over the face of the board as it dries, and will expand just over 1/8” when it swells.

The winner (by a landslide): Thermally Modified Hemlock

Thermally modified Hemlock (Hem-Fir) has a beautiful range of warm natural color tones and graining

Thermally modified Hemlock (Hem-Fir) has a beautiful range of warm natural color tones and graining

DOWNLOAD MATAVERDE THERMAWOOD HEM FIR BROCHURE

Durability

Durability testing measures how long a particular wood species is expected to last when subjected to insects (like ants and termites) and various fungi that will cause wood to rot and decay. KD Hemlock is rated moderately resistant to insects. Moderately durable means an expected service life of 10-15 years. For KD hemlock resistance to decay, it is rated durable (15 -20 years).

Because thermally modifying Hemlock ‘cooks’ the sugars out, it is rated ‘very resistant’ to both insects and decay. Under normal conditions you should expect a service life of 25+ years with thermally modified hemlock.

Clear-cut winner: Thermally Modified Hemlock

Fastener Withdrawal

The pull-out strength of KD Hemlock is about 80% stronger (screws) and 90% stronger (nailing) than thermally modified Hemlock. To put that in perspective, thermally modified hemlock has the identical pull-out strength as Western Red Cedar.

Winner: KD Hem Fir

Paint Adhesion

Kiln dried hemlock holds paints and stains about 15% better than thermally modified hemlock. That’s why oil-based stains and paints should be used with thermally modified Hem Fir.

Winner: KD Hemlock

Thermally modified hemlock siding may be stained or painted beautifully with oil based finishes

Thermally modified hemlock siding may be stained or painted beautifully with oil based finishes

RELATED: CARE AND MAINTENANCE GUIDELINES FOR THERMAWOOD HEM FIR

Milling and Workability to National Lumber Grades Authority (NLGA) guidelines

- Thermally modified hemlock mills 117% smoother than KD hemlock on knotty wood

- Thermally modified hemlock has 131% less milling defects on clear grade material

Winner in both categories: Thermally modified hemlock

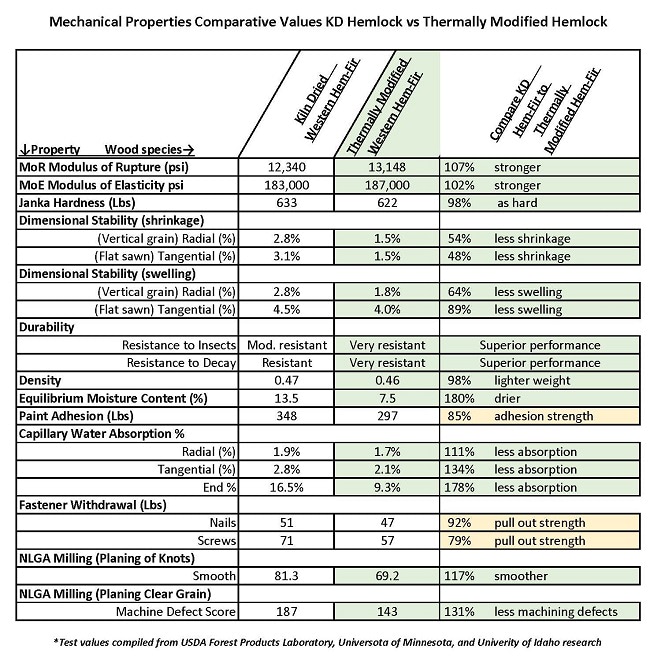

Mechanical properties and Comparisons between KD Hemlock and thermally Modified hemlock

If you are a mechanical properties nerd (guilty), please check out the actual data and comparisons of mechanical properties and performance criteria for both KD Hemlock and thermally Modified hemlock below.

DOWNLOAD HEM FIR MECHANICAL VALUES CHART

Please CONTACT US and let us know if we can provide additional information.

Need a better look at thermally modified wood siding?

Request rainscreen siding samples today.

Interested in more information about wood rainscreen siding?

Download the Ultimate Guide to Wood rainscreen siding today.

Related Posts