For decades, Western Red Cedar has been the gold standard for softwood siding for builders, designers, and homeowners. And why not? Cedar siding is naturally beautiful, performs well and was readily available. Well, there’s a new option available and we think you'll like it. An innovative thermally modified hemlock wood siding, Mataverde ThermaWood Hem-Fir. And you will want to check it out.

Mataverde ThermaWood thermally modified Hem Fir is available for siding, fences, trim and more

Thermally Modified Hemlock vs. Cedar: An Introduction

Thermally Modified Wood vs. Kiln Dried

Kiln Dried Wood

Kiln drying lumber is a great way to get some of the moisture out of wood to shrink it and help it become more dimensionally stable. Green lumber is placed into a kiln at predetermined temperatures for a set number of hours (or days) based on best results for a particular wood species. Finding the right ‘recipe’ for kiln drying various wood species has been developed, through trial and error, for a long time. This is called the kiln drying schedule.

Thermally Modified Wood

Thermal modifying wood is like kiln drying, except moisture is either added, or remains in the kiln under pressure, and the wood is heated to higher temperatures than kiln drying. The moisture keeps the wood from misbehaving during the drying process. The higher temperatures ‘cook’ the sugars out. This makes thermally modified wood more resistant to insect damage and more decay resistant. The moisture helps the wood become more dimensionally stable.

When softwood lumber species are thermally modified, it usually makes the wood harder, more rot resistant, and more stable (less movement) than the original wood. On the downside, it usually makes the thermally modified wood a little more brittle than the original wood. However, thermally modified hemlock performs better in many ways.

The unique process used for Mataverde Thermally Modified Western Hemlock (Hem-Fir) employs a vacuum kiln. The vacuum kiln creates increases the pressure, so it takes less heat to ‘cook’ the sugars out of the wood. This thermal modification process uses much less energy. And the finished siding product is beautiful, and exceptionally stable.

RELATED: Thermally Modified Hem Fir Wood Siding Information

Thermally Modified Hemlock vs. Cedar: Aesthetics

Beauty is in the eye of the beholder. Most people find Western Red Cedar to be gorgeous. Count me in.

Western Red Cedar siding installed on a coastal rainscreen siding project

Western Red Cedar siding installed on a coastal rainscreen siding project

Thermally Modified Hem Fir siding is beautiful, too. Because the thermal modification process of Hemlock tends to darken the wood slightly, you will find the color to be more consistent than Cedar. Both of these two softwood siding options look great. You decide.

%20ThermaWood%20FR%20Hem-Fir%20Siding%20Project%202024/ThermaWood%20FR%20Hem-Fir%20Siding%20EXterior%20Front%20View%20The%20Ridge%20House%20project%20CA.jpg?width=800&height=534&name=ThermaWood%20FR%20Hem-Fir%20Siding%20EXterior%20Front%20View%20The%20Ridge%20House%20project%20CA.jpg)

Thermally Modified Hemlock siding can be finished beautifully with oil-based stains or paints

RELATED: Check out the Thermally Modified Hem Fir Wood Siding Photo Gallery

Want to see even more? Are you ready to see ThermaWood Hem-Fir for yourself? Order samples today.

Availability & Affordability: ThermaWood Hem-Fir vs. Western Red Cedar Siding

Nowadays, Red Cedar isn’t always as readily available as it once was. Sometimes red cedar, especially the upper grades, are quite difficult to find. And when supplies get low, cedar prices tend to rise. Sometimes quickly and often steeply.

Thermally Modified Western Hemlock (Hem-Fir) on the other hand, is readily available, and the pricing is not as volatile as Red Cedar, especially in the upper grades, like A& Better grade and C+ Better grades. Because thermally modified hemlock is more obtainable, it is usually ready for your project a lot faster, and the pricing is less susceptible to sharp price increases.

Visit our siding price comparison page for the latest pricing of all types of siding materials, including cedar and thermally modified Hemlock.

ThermaWood Hem-Fir vs. Western Red Cedar Siding

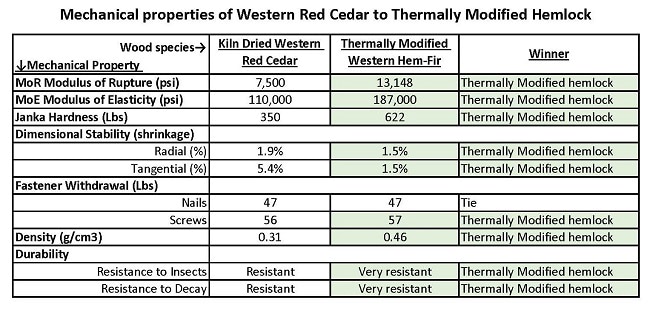

Thermally Modified Hemlock (Hem-Fir) is much stronger than Western red cedar. Scientific testing confirms that Therma Hemlock is almost twice as difficult to break than western red cedar (Modulus of Rupture test). Thermally modified hem-fir is also 70% less brittle than red cedar (Modulus of Elasticity test).

The winner: Thermally Modified Hemlock

Thermally modified hem-fir siding

Hardness Comparison: ThermaWood Hem-Fir vs. Cedar

When measuring the hardness of wood using the Janka hardness test, thermally modified hemlock is almost twice as hard as red cedar.

It takes 622 lbs. of pressure to put a .444” diameter steel ball halfway into a piece of thermally modified hemlock.

It takes 622 lbs. of pressure to put a .444” diameter steel ball halfway into a piece of thermally modified hemlock.

It takes only 350 pounds of force to embed the same steel ball halfway into a piece of red cedar (very soft).

The winner: Thermally Modified Hemlock

Dimensional Stability: ThermaWood Hem-Fir vs. Cedar

When you hear people discussing wood ‘stability’, they are referring to the dimensional stability of wood. All woods will expand when moisture is added. And all wood will shrink when moisture is taken away. Dimensional stability testing measures exactly how much each piece of wood will expand (swelling) and contract (shrinkage) when water is added or taken away. Thermally modified woods are almost always far more stable than their non-modified counterparts.

Kiln Dried Vertical Grain Western red cedar is very stable. It shrinks about 2%. Flat grain red cedar, however, expands up to 5%.

Thermally modified hemlock is significantly more stable than Western red cedar. ThermaWood hemlock exhibits exceptionally little expansion and contraction. And because the hemlock boards are thermally modified in a vacuum kiln, the results are very impressive.

Vertical grain thermally modified hemlock siding shrinks 1.5% as it dries. Vertical grain thermally modified hemlock siding swells up to 1.8% as it picks up moisture. That is why it is considered highly stable.

- For example, when you take a piece of 1 x 6 of vertical grain thermally modified hemlock, it will expand or contract much less than 1/8” over the face of the board.

- A piece of 1 x 6 Vertical Grain Western Red Cedar will expand just under an eight inch.

- A piece of 1 x 6 flat sawn Western red cedar may shrink more than a quarter inch.

The winner (by a landslide): Thermally Modified Hemlock

Clear vertical grain Thermally Modified Western Hem Fir has a lovely range of color tones

DOWNLOAD THERMALLY MODIFIED HEM FIR BROCHURE

Compare Durability: ThermaWood Hem-Fir vs. Cedar

Durability testing measures how long a particular wood species is expected to last when subjected to insects (like ants and termites) and various fungi that will cause wood to rot and decay.

Western Red Cedar is rated between moderately resistant to resistant against both insects and decay. Moderately resistant means an expected service life of 10-15 years. Resistant means the wood should hold up for up to 15 -20 years.

Because thermally modifying Hemlock ‘cooks’ the sugars out, it is rated ‘very resistant’ to both insects and decay. Under normal conditions you should expect a service life of 25+ years with thermally modified hemlock.

Whether you are installing your siding in a traditional shiplap or tongue and groove (T&G) profile, or prefer a rainscreen siding design and installation, both species are very good options to consider.

Clear-cut winner: Thermally Modified Hemlock

Interested in learning more about rainscreen siding design and installation?

Download the "Ultimate Guide to Wood Rainscreen" today.

Fastener Withdrawal: ThermaWood Hem-Fir vs. Cedar

The pull-out strength of Western Red Cedar and thermally Modified Hemlock are almost identical for nail pull-out. Thermally modified hemlock has slightly higher strength for screw pull-out than Western Red Cedar.

Winner (by a nose): Thermally modified hemlock.

Mechanical Properties: ThermaWood Hem-Fir vs. Cedar

Overall, you have two very beautiful softwood siding options to choose from. Both species perform well in a rainscreen siding system or in a tongue and groove siding profile. Please check out the actual test results and mechanical properties and performance criteria of Western Red Cedar vs. Thermally Modified Hemlock (Hem-Fir) chart below. The test values are compiled from research conducted by the USDA Forest Products Laboratory, University of Minnesota, and the University of Idaho.

Related Posts