Architects and home builders in wildfire-prone regions are continually encountering challenges as fire codes increase. One of the biggest is finding real wood siding with both fire retardant treatment and design versatility. A new and different wood siding material offers hope. Hear why this seasoned custom home builder and architect team chose Mataverde® ThermaWood FR Hem-Fir Siding over all the others.

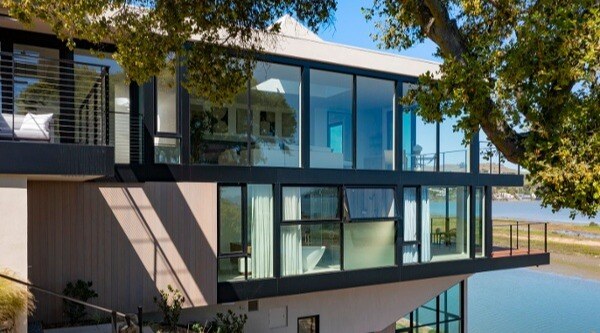

The Ridge House, a custom home fire rebuild project in Northern California that prominently features Mataverde® ThermaWood FR Hem-Fir Siding in the contemporary design.

The Ridge House, a custom home fire rebuild project in Northern California that prominently features Mataverde® ThermaWood FR Hem-Fir Siding in the contemporary design.

In this article:

A Solution to Meager Fire Resistant Lumber Options

In areas susceptible to wildfires, choosing fire-resistant materials has never been more important. Mataverde® ThermaWood FR Hem-Fir Siding is earning a well-deserved reputation as a standout among the usual options.

Specifically for these remarkable qualities:

- WUI certification (Wildland Urban Interface)

- IWUI Certification (International Wildland Urban Interface)

- Passed the California 10-Year Weathering Test

- Permanent fire-retardant treatment that will not shed or wash off.

- Non-toxic thermal modification and fire-retardant process

- Durability and longevity

- Aesthetic appeal, frequently compared to Cedar

- Offers design flexibility

- Cost effective and saves time and labor

Could this list be too good to be true? Surprisingly, no. Read on to learn how these benefits helped ThermaWood FR Hem-Fir Siding surpass both the builder’s and architect’s expectations in this inspired exterior siding design home project.

Take a video tour of this project to see how ThermaWood FR Hem-Fir Siding A&BTR T&G was used on this contemporary, sleek fitting design, including soffits and in the outdoor kitchen. Then ThermaWood Hem-Fir was used in the interior on 18' ceilings to mirror the outside look and create a warm and intimate feeling space.

Click here to share from our YouTube Channel here

Fire Rebuild Projects Need Special Consideration

As far too many people on the West Coast have experienced, the original home on this beautiful hillside was swept away by wildfire. When the landscape began to regenerate its natural beauty, the homeowners decided to rebuild in the location they loved.

Custom builder, Robin Guilfoyle, owner of RobinWood Construction, and architect Chris Cahill, owner of Cahill Studio, were chosen for this responsibility. They spoke with us at length about bringing this impressive design, The Ridge House, to life with ThermaWood FR Hem-Fir Siding and their satisfaction with the results.

Robin and Chris started out facing two big hurdles:

- Meeting the ever-increasing fire code regulations that are moving faster than the building material industry can keep up.

- Achieving the contemporary design aesthetic the client wanted with the limited fire-resistant siding options available.

“It's a complete paradigm shift in California,” said Robin, and that builders “now talk about a ‘fifth season’” in the construction industry. He elaborated, “there’s a fire season that starts in September and goes till November or December, depending on how much rain we get in the fall … it is something that is reality. It's not going to go back to the way it was before, so it's just something that we must be aware of and build for.”

A Solution to Challenges Building in Wildfire-Prone Areas

"It became the direction we wanted to go with siding. We can keep the exterior look of wood,” instead of settling for fiber cement or fireproof paint.

Meets The Highest Level Fire Code Certifications

Builders and architects can be confident in specifying ThermaWood FR Hem-Fir Siding because it carries both WUI and IWUI certifications. It also surpassed the rigorous California 10-year weathering test.

The aesthetic and design considerations were important, but as Robin said, “of course the biggest factor, to be honest, was that it was a fire-resistant product that gives us the rating … we want for safety, to give the clients that peace of mind.”

RELATED: ThermaWood FR Hem-Fir Siding: Redefining the Fire Retardant Siding Industry?

Customers are "thrilled with it…the guys in the field have said it checked all the boxes" and "takes finishes with no issues."

- Dan Weaver, Healdsburg Lumber

%20ThermaWood%20FR%20Hem-Fir%20Siding%20Project%202024/ThermaWood%20FR%20Hem-Fir%20Siding%20Outdoor%20KItchen%20interior%20view%20The%20Ridge%20House%20project%20CA.jpg?width=973&height=1131&name=ThermaWood%20FR%20Hem-Fir%20Siding%20Outdoor%20KItchen%20interior%20view%20The%20Ridge%20House%20project%20CA.jpg)

A Real Wood Siding That Rivals Cedar

Along with its impressive fire-retardant properties, Mataverde ThermaWood FR Hem-Fir Siding is a real wood. It rivals traditional options like Western Red Cedar and Alaskan Yellow Cedar in durability, natural beauty, and color.

Chris Cahill had designed a contemporary exterior façade of vertical cedar siding for The Ridge House, specifically in Alaskan Yellow Cedar, for a lighter color palette. Fireproof paint was one option considered to meet the fire code and achieve the look he wanted, but it wasn’t optimal. Fiber cement siding was considered but isn’t available in sizes that could achieve the tight fitting, contemporary look he was after.

Both options would be big compromises to the fire codes over the aesthetic of the design. Robin went back to Healdsburg Lumber to see what else was possible and his rep, Dan Weaver, suggested ThermaWood FR Hem-Fir Siding.

When asked why he suggested it, Dan was enthusiastic about the features it offers his customers. “It’s beautiful,” said Dan, “it looks so much like Western Red Cedar” at a competitive price. That with the fire retardant treatment, piqued his interest. The strength and decay resistance that the thermal modification lends also lends confidence in recommending it to his long-time homebuilder customers like Robin.

Dan mentioned that, so far, his customers who have used it, “were thrilled with it…the guys in the field have said it checked all the boxes" and reported that “it takes finishes with no issues.”

ThermaWood FR Hem-Fir Siding has a clear vertical grain and a light to medium brown tone color range, deepened the heat process. In combination with the fire-retardant treatment this made it a very viable wood siding option for this project.

After learning this, Robin tells he “picked up some sample boards and put them on a quick frame wall,” so Chris could see “how it looked in comparison to the cedar”. They also tested the stain colors Chris preferred on the ThermaWood FR Hem-Fir Siding samples.

Their reaction? “Well, that’s fantastic!”

“That became the direction we wanted to go with siding. We can keep the exterior look of wood,” said Robin, instead of settling for fiber cement or fireproof paint.

Chris concurs. “Fortunately, we discovered this wood siding product,” ThermaWood FR Hem-Fir Siding, “which ended up meeting several criteria” he said. He is also familiar with the stability and durability that thermally modification offers.

Is ThermaWood FR Hem-Fir Siding is right for your next project?

Decide for yourself! Request a sample now and start the journey.

“Just the fact that it was cheaper than the Cedar, the same labor to use it and put in the

details that we want ... I think that made it a no-brainer.

Really, there was no reason to not go with it”

-Robin Guilfoyle, RobinWood Construction

Project Budget Advantages, Especially Over Cedar

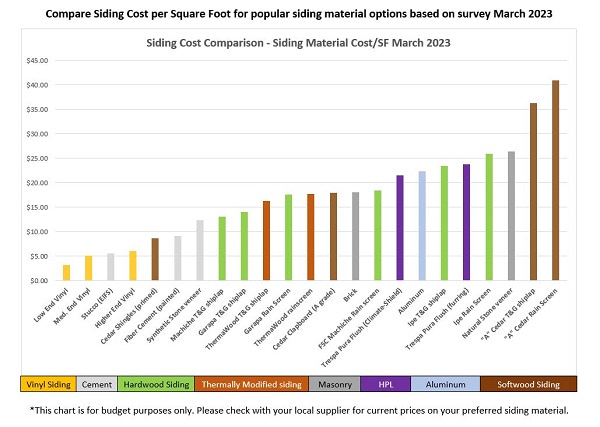

While prioritizing safety is paramount in wildfire rebuild projects, budget constraints are still important. ThermaWood FR Hem-Fir Siding offers a cost-effective solution without compromising on quality or performance, ensuring that projects stay within budget without sacrificing safety or design.

Chris said, “The cost was competitive to the alternatives on the market. That was part of the decision process.”

“Just the fact that it was cheaper than the Cedar and the same labor to use it and put in the details that we want into our projects,” said Robin, “I think that made it a no-brainer. Really, there was no reason to not go with” the ThermaWood FR Hem-Fir Siding.

The most significant include:

-

Much more affordable than Cedar, and competitively priced versus fiber cement.

-

Saves time and money in materials, time, and labor over non-fire treated wood siding options, which require additional material to meet the fire codes.

-

The fire-retardant treatment process is done before it is delivered, saving the step of on-site application.

RELATED: ThermaWood FR Hem-Fir Siding Project Photo Gallery

A Non-toxic Fire-Retardant Siding Material

ThermaWood FR Hem-Fir Siding undergoes a non-toxic thermal modification process using only heat and steam under pressure. This makes the wood very stable and resistant to rot and decay. The fire-retardant treatment, Thermex-FR is also non-toxic, a non-Boride based process that will not shed or wash off, ensuring safety for the installer, the occupants, and the environment. It outperforms other exterior fire treatments by far.

This is also a huge consideration for the homeowners, since it is safe for families and pets to live around. It’s also a factor for the installers working with it.

For Robin and his crew, “the non-toxicity was beneficial because we didn't have to specifically wear masks … I checked on that first before we even started. Because that is a factor dealing with cementitious products,” and other common siding materials that are hazardous.

“It's difficult to work with some fire-retardant materials [that] we worked with in the past, that have inherent issues,” Robin said, and “we didn't really want to go in that direction.”

Permanent Fire-Retardant Treatment

Commonly used fire-retardant treatments are made of Boride-based or other water soluble chemicals with a topical application. This allows it wash off, or shed off, over a relatively short period of time.

The innovative fire-retardant treatment used on ThermaWood FR Hem-Fir Siding, Thermex-FR® by Chemco, bonds with the wood at a cellular level. This permanent fire-retardant treatment is certified safe for use on the interior and exterior of your project, offering long-lasting protection and peace of mind for you and the homeowners.

Plus, ThermaWood FR Hem-Fir Siding arrives on site already treated, eliminating the on-site application step.

Watch how the permanent Thermex-FR fire retardant treatment is processed in this video from Chemco

Thermally Modified Wood Has Increased Durability

Fire retardancy is only one concern, siding material should also be long lasting and resistant to environmental threats. The thermal modification process of ThermaWood FR Hem-Fir Siding offers both advantages.

The innovative thermal modification process used on ThermaWood FR Hem-Fir Siding is a patented combination of heat and steam in a pressure kiln. This creates a modified wood that has increased strength, decay and insect resistance, and longevity.

Offers Big Design Versatility and Flexibility

Architects operating in fire-prone areas face the unique challenge of balancing safety requirements with design aesthetics. ThermaWood FR Hem-Fir Siding provides architects with unparalleled design versatility, allowing them to create stunning structures while adhering to fire safety regulations.

A Less Bulky Siding Assembly

From a design perspective, “the fact that this is a product that is pre-treated and that does not require that additional layer of substrate,” to meet the statewide fire codes, said Chris, “eliminates another bulky layer to the to the construction assembly” plus saves “time and money.”

We asked Robin his thoughts on working with the additional material needed to meet their state fire codes. “Nobody likes to put up DensGlass behind the wood siding,” said Robin, it’s “difficult to install if you're using cedar or siding material that doesn't have the rating.”

“I didn't want to adapt siding material. I wanted something that was flush and looked very modern and contemporary."

- Chris Cahill, CahillStudio

Board Sizes Give Style Flexibility

Robin found the “diversity of sizes” a plus. “I'm known for my details, and I'm very picky about reveals and how things come together and how it shows” on the finished exterior.

“There's a good variety of sizes available…so that we could manufacture our own trim pieces, and adapting pieces to mesh with other materials, corners, and windows. That’s also very advantageous. With other products, they're quite limited in what they offer in sizes and not as easy to create the details that I like,” said Robin.

Chris saw the same advantage. “We were also able to have this siding material milled in a way that creates a tongue and groove application, so it's smooth but joined together.” He said, “I didn't want to adapt siding material. I wanted something that was flush and looked very modern and contemporary,” and the ThermaWood FR Hem-Fir Siding met that goal.

Robin mentioned that the alternative, fiber cement boards, would limit them to a more farmhouse-style exterior that didn't fit with the design.

Chris was also pleased to eliminate the traditional trim casings along the doors and windows, which “allowed the siding to just butt up flush against the headers of the windows and sills.” Chris said this achieved “a very sleek” detail, as he designed. “There's a very uncluttered kind of application to this wood siding on the exterior,” he said, “we were able to do everything that we wanted to do.”

Siding Color Application

Chris appreciated the similar look to Cedar as well as the ability to use oil-based stains.

“My intention was to look to the natural surroundings to for the color.” He planned a mossy green and mossy gray palette using different stain combinations, using a semi-solid stain that would let the wood grain show through.

He said that he and Robin, “weren't exactly sure what we were going to end up with because we were applying the stain after it had been treated.” Especially because the ThermaWood FR Hem-Fir Siding was a prominent design material.

“It was always an unknown” going into the project, “but we are so very, very pleased” with the results.

Request a sample now of ThermaWood FR Hem-Fir Siding.

Compare it your your other options and see the appeal for yourself.

"It ended up meeting several criteria … a high level of fire resilience, a thermally

treated material, a good solution to Western Red Cedar or Alaskan Yellow Cedar, which

is a product that I use in a lot of my projects . It did meet those criteria very well .....

- Chris Cahill, CahillStudio

Aesthetic Appeal of Real Wood

Along with its impressive fire-resistant properties, ThermaWood FR Hem-Fir Siding boasts the natural beauty of real wood, rivaling traditional options like Western Red and Alaskan Yellow Cedar. ThermaWood offers a clear vertical grain, with a natural wood color range deepened by the heating process to a range of light to medium brown tones.

The ThermaWood FR Hem-Fir Siding, “ended up meeting several criteria that we had, which was a high level of fire resilience plus, it’s a thermally treated material. And we were looking for something that would be a good solution to Western Red cedar or Alaskan Yellow Cedar, which is a product that I use in a lot of my projects “, Chris said. “It did meet those criteria very well.”

They were happy that it would take stain, but “we weren't exactly sure what we were going to end up with because applying the stain after it had been treated was always an unknown. But we were so very, very pleased” with the result, especially because ThermaWood is “a very prominent material” in the design.

Sustainability and Environmental Benefits

In an era of increasing environmental awareness, sustainable building materials are more important than ever. ThermaWood FR Hem-Fir Siding promotes sustainability by utilizing responsibly sourced, domestic lumber. It also boasts a low carbon footprint from harvest to treatments to the distribution warehouse, making it an environmentally friendly choice for wildfire rebuild projects. Plus, ThermaWood FR Hem-Fir Siding can be recycled at the end of its useful life.

Robin said that for his projects, “Sustainability is a consideration…just for myself and in my own life. I definitely think along those lines, and there's many products that have a huge carbon footprint that I just try and stay away from.” When considering ThermaWood FR Hem-Fir Siding for this home rebuild, sustainability “was brought up in the beginning” and he considered that an advantage.

ThermaWood FR Hem-Fir Siding "was actually beyond expectation.”

With fire retardancy, size options, and many other features,

“all those things just made it so much easier.”

- Robin Guilfoyle, RobinWood Construction

"We feel that it's a great product for what we are achieving here in Northern California."

-Chris Cahill, CahillStudio

And the end result?

The architect was very satisfied with the overall design and would like to use this material again. “Sustainability is always a topic with clients, especially in this part of California,” said Chris. But in this case, we were looking for something that really was going to satisfy all the criteria including fire resiliency, longevity, cost efficiency and appearance. So, it ticked all the all the boxes.”

“Everybody's very happy,” with both the interior and exterior. Robin says, “The different color stains came out great. The end product, I think, just speaks for itself. The clients were very happy with the final look.”

And Robin’s experience as a builder? The ThermaWood FR Hem-Fir Siding "was actually beyond expectation.” Including fire retardancy, several size options, and many other features. “All those things that just made it so much easier,” Robin said.

He added that his crew, “were happy working with it because it wasn't a cementitious product which is difficult in many ways, and it was just like working with cedar,” Robin said. He said cutting cedar, “that's like butter. It’s something that we really like working with.” The ThermaWood FR , “works just the same, which just pleased everybody.”

Both Chris and Robin enthusiastically said they would use ThermaWood FR Hem-Fir Siding again and are already planning the next projects. Chris said, “we feel that it's a great product for what we are achieving here in Northern California.”

Chris Cahill and Robin Guilfoyle have made it clear that ThermaWood FR Hem-Fir Siding checked off all of their siding design project criteria. From the WUI and IWUI certifications, to design versatility, to sustainability, this is a siding material that overcomes obstacles to building in wildfire-prone areas. And they feel other options just can’t do that.

We hope you enjoyed this article. Questions? Contact us, we’re happy to help.

Would you like to see ThermaWood Fr Hem-Fir siding or decking samples for yourself?

REQUEST THERMAWOOD FR SAMPLES TODAY

Are you ready to see if ThermaWood FR Hem-Fir siding meets your budget?

REQUEST A THERMAWOOD FR SIDING QUOTE

Related Posts

%20ThermaWood%20FR%20Hem-Fir%20Siding%20Project%202024/ThermaWood%20FR%20Hem-Fir%20Siding%20exterior%20soffit%20view%20The%20Ridge%20House%20project%20CA-1.jpg?width=973&height=503&name=ThermaWood%20FR%20Hem-Fir%20Siding%20exterior%20soffit%20view%20The%20Ridge%20House%20project%20CA-1.jpg)

%20ThermaWood%20FR%20Hem-Fir%20Siding%20Project%202024/ThermaWood%20FR%20Hem-Fir%20Siding%20side%20breezeway%20view%20The%20Ridge%20House%20project%20CA.jpg?width=973&height=649&name=ThermaWood%20FR%20Hem-Fir%20Siding%20side%20breezeway%20view%20The%20Ridge%20House%20project%20CA.jpg)

%20ThermaWood%20FR%20Hem-Fir%20Siding%20Project%202024/ThermaWood%20FR%20Hem-Fir%20Siding%20side%20entryway%20view%20The%20Ridge%20House%20project%20CA.jpg?width=973&height=649&name=ThermaWood%20FR%20Hem-Fir%20Siding%20side%20entryway%20view%20The%20Ridge%20House%20project%20CA.jpg)

%20ThermaWood%20FR%20Hem-Fir%20Siding%20Project%202024/ThermaWood%20FR%20Hem-Fir%20Siding%20Outdoor%20KItchen%20Front%20View%20The%20Ridge%20House%20project%20CA.jpg?width=973&height=648&name=ThermaWood%20FR%20Hem-Fir%20Siding%20Outdoor%20KItchen%20Front%20View%20The%20Ridge%20House%20project%20CA.jpg)

%20ThermaWood%20FR%20Hem-Fir%20Siding%20Project%202024/ThermaWood%20FR%20Hem-Fir%20Siding%20Outdoor%20Kitchen%20Side%20View%20The%20Ridge%20House%20project%20CA.jpg?width=973&height=637&name=ThermaWood%20FR%20Hem-Fir%20Siding%20Outdoor%20Kitchen%20Side%20View%20The%20Ridge%20House%20project%20CA.jpg)

%20ThermaWood%20FR%20Hem-Fir%20Siding%20Project%202024/ThermaWood%20FR%20Hem-Fir%20Siding%20Side%20Window%20View%20The%20Ridge%20House%20project%20CA.jpg?width=649&height=973&name=ThermaWood%20FR%20Hem-Fir%20Siding%20Side%20Window%20View%20The%20Ridge%20House%20project%20CA.jpg)