Related Posts

“Because it is an organic natural material, all wood moves, and will continue to move throughout its life cycle. Here are some tips on how to work best with this.”

Wood is an all-natural and beautiful building material that can be used in so many ways to create and build new designs. Wood is prized as an easily workable material and as a fully renewable natural resource. Because it is an organic material, all wood moves, and will continue to move throughout its life cycle. Regardless of how long a board has been dried, no matter what type of sealer was used and how it was fastened, all wood will continue to move, naturally. The best way to deal with wood movement is to minimize its effect and plan your project design accordingly to work with wood’s natural characteristics.

In its natural growing state, wood grains run vertically and carry the water up to nourish the tree. As soon as a tree is cut down, it will naturally start to shed its water. When the tree is cut into logs and then boards, even more water will be shed. As wood loses its moisture, the cells collapse and shrink and the wood itself starts to shrink. If the same piece of wood then starts to pick up moisture, it will expand in size. All wood continues this natural expansion and contraction process based on the changing humidity content of its environment.

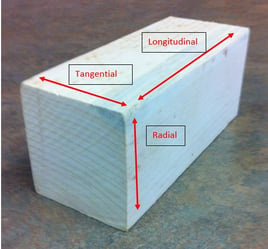

Wood shows very little movement longitudinally (lengthwise). Wood shows a lot more movement in thickness and width, radially (perpendicular to the grain), and especially tangentially (across the grain). The grain in “flat sawn” boards are oriented tangentially width wise, that’s why flat sawn boards typically show a little more expansion and contraction width wise than “quarter sawn” or “rift sawn” boards.

Wood shows very little movement longitudinally (lengthwise). Wood shows a lot more movement in thickness and width, radially (perpendicular to the grain), and especially tangentially (across the grain). The grain in “flat sawn” boards are oriented tangentially width wise, that’s why flat sawn boards typically show a little more expansion and contraction width wise than “quarter sawn” or “rift sawn” boards.

As you can see in the picture, tangential movement is in the direction across the wood’s growth rings. Wood movement is the greatest in this direction.

Radial movement (perpendicular to the wood’s growth rings) can be significant, too, but is usually about half the amount of tangential shrinkage or expansion.

Each wood species will move at different rates, and it is important to know that every board and even different parts of the same board will move at different rates. There has been much testing performed on various wood species by the USDA Forest Product Laboratory and many other well respected scientific organizations. Here is a link to the test data and characteristics of numerous wood species. Please note the measurements are averages and that each board will vary slightly due to its unique natural characteristics.

Proper kiln drying is the most effective method to help stabilize and minimize wood movement. When wood is taken from green lumber and dried to a lower moisture content, most of the major shrinkage has already taken place. That said, all wood, even kiln dried lumber, will move as the humidity content changes in its environment. All wood strives to be at equilibrium with its surroundings.

If two deck boards expand or contract at different rates while acclimating - don't use them in the same row.

Many steps can be taken to help minimize wood movement – but nothing can prevent wood from moving completely. Applying a proper sealer is helpful, proper fastening is also helpful, but truly, the only way to deal with wood movement is to anticipate it and work with the wood’s natural characteristics and build your project accordingly.

If your wood is being used outdoors, such as a decking, siding or lumber for another exterior project, it is imperative to allow your wood to slowly acclimate to your local site conditions – outdoors. There are a lot of crucial ‘do’s and don’ts’ to properly acclimate your exterior wood, please click here for a helpful list of proper acclimation guidelines.

For interior woods, such as trim, boards and flooring, they dry best with good ventilation and very little heat. The drier the air and hotter the temperature, the faster the wood will dry. Drying wood s-l-o-w-l-y works best to achieve better looking and better performing wood products. Drying wood too quickly can create unwanted problems such as twisting, checking, cupping and warping.

We hope you found this article helpful. Please visit our website for more information about acclimation, finishing and care and maintenance of exterior wood products.

Finishing options for decking and sidings

Care and maintenance of wood decking and siding

If you would like more information about decking or siding, please download these helpful guides today: