How Can You Minimize the Amount of Cupping in Deck Boards?

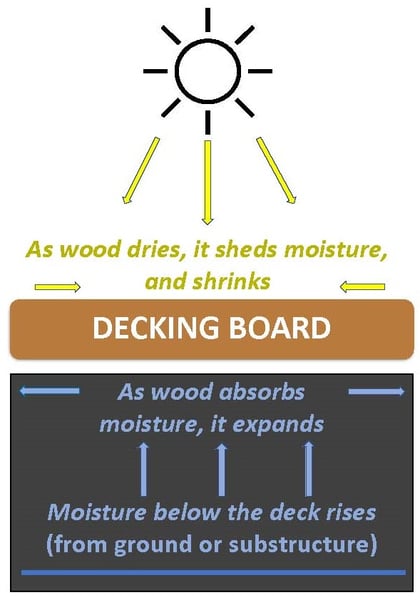

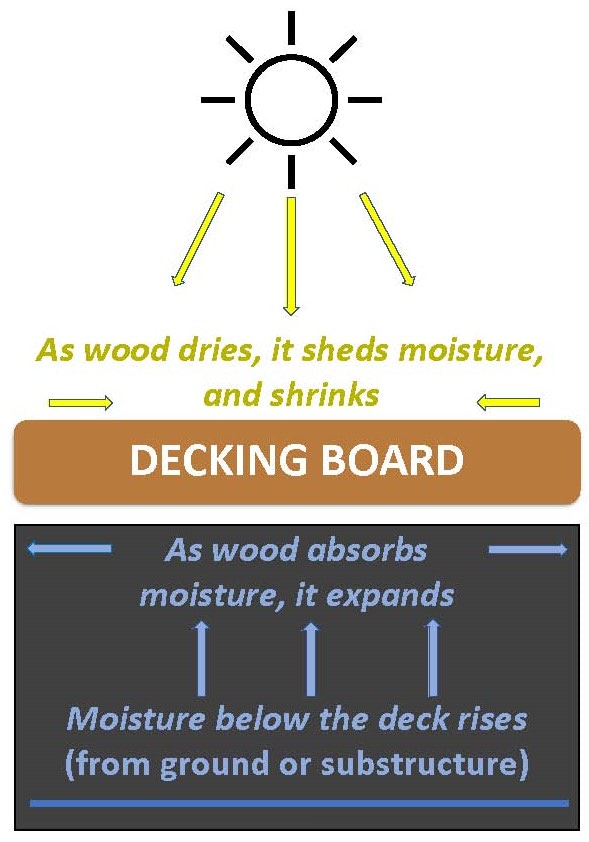

Creating a balanced deck design and structure starts in the planning and design process. Short of putting a roof over your deck, there's not a whole lot of things you can do to minimize the sunlight. So, controlling and minimizing the amount of moisture below your deck is your best option.

Here is a list of some best demonstrated practices for long-lasting deck performance:

-

Build decks as high above grade as possible. 30” is considered the minimum for best performance. Anything less than 30” is considered a ‘low clearance’ deck.

-

Make sure there is proper grading below your deck. pitch the ground away from your home or structure. Get the water out of there! Standing (or sitting) water creates an unacceptably moist below-deck environment.

-

Make sure there is adequate drainage to allow rain and bulk water to escape from below the deck. Some landscape architects and master deck builders use landscape fabric below the deck to keep the moisture in the ground.

-

Some experts will then place a layer of gravel on top of the fabric to handle rain water from above. And since the ground is already pitched it flows out from below the deck at a controlled rate.

-

Plan adequate below-deck ventilation. Ventilation on three sides is ideal. Proper air flow helps eliminate unwanted moisture. Two sides with cross-ventilation is next best.

-

Always properly acclimate your deck boards to site conditions - before installation.

-

Pre-finishing your deck boards with an appropriate sealer on all four sides, before installation, helps protect your investment.

Or, if you're a big risk taker, you can 'roll the dice' and take your chances, and see what happens. Like this failed installation:

Here's what can happen without proper prior planning

Oh my! When the cupped deck boards in this picture were removed for inspection, the top of the boards were bone dry. The bottom of the deck boards are literally soaking wet. In addition to the expected cupping in these conditions, you can see black mold growing where the deck boards were sitting on the joists. This is a bad environment for the decking and the joists.

Additional Requirements for Best Performance of Low Clearance Decks

Low clearance decks are the worst-case scenario for deck boards. Limited air flow and imbalanced moisture conditions are extremely tough on wood decking. Special steps and design considerations are needed for best performance.

-

Use thicker deck boards. 21 mm or 5/4 thick nominal decking is heftier and much less likely to cup as much as a thinner (1 x nominal thickness) deck board

-

Narrower boards work best. 4” nominal (3-1/2” actual) wide deck boards perform better than wider (6” nominal) deck boards.

-

4” nominal deck boards expand and contract less than wider boards

-

Because there are more gaps between the deck boards, 4” nominal deck boards provide about 44% more top of deck ventilation than 6” nominal decking.

-

Face screws provide more secure fastening than hidden fasteners. This is especially important for low clearance decking.

Trying to decide on the best decking material option for your project?

Download the "Ultimate Guide to Selecting the Right Decking" today

Check out other Decking Material Options

Need some deck design ideas? Looking for some fresh deck ideas?

Download the "Deck Design Ideas Book" now

61 pages with over 150 real decking projects and deck ideas

Check out Decking Project Galleries

Related Posts