DECK FASTENING METHODS AND FASTENERS

For Mataverde Premium Hardwood Decking Material

If you are using a high-density hardwood decking material for the first time, you will find that a new set of deck installation techniques and deck fasteners is required. Read on for helpful information regarding methods and products to make correct installation easier with all Mataverde Hardwood Decking products.

DECKING SCREW DOWN METHODS

Screwing your Mataverde Premium Hardwood Decking directly to the deck substructure is the strongest method for securing your deck boards.

The two most effective methods of installing decking screws are:

-

The traditional pre-drilling, countersinking, and deck screwing methods can be completed in two steps.

- The “Ejector Screw” deck screw method where the drilling, countersinking, and screwing of deck screws are performed in one quick step.

Regardless of which screw-down method you choose to install your hardwood deck, the following chart is a handy guideline for estimating the proper quantity and placement of decking screws:

DECK FASTENER REQUIREMENTS |

||||||

| 16” On Center Supports | 24” On Center Supports | |||||

| Deck Board Nominal Size | 1 x 4 | 1 x 6 | 5/4 x 4 | 5/4 x 6 | 5/4 x 4 | 5/4 x 6 |

| Stainless Steel Decking Screws | 5.7 screws / sq. ft. | 5.5 screws / sq. ft. | 5.7 screws / sq. ft. | 3.6 screws / sq. ft. | 4 screws / sq. ft. | 2.6 screws / sq. ft. |

| 2-1/4” Deck screws | 2 per joist | 3 per joist | 2 per joist | 2 per joist | 2 per joist | 2 per joist |

Need some help deciding what decking material is right for your project?

Download the free "Ultimate Guide to Selecting the Right Decking" now.

TRADITIONAL PRE-DRILLING AND SCREWING METHOD

A craftsman using high-density hardwood decking for the first time will find that a new set of deck installation techniques and deck fasteners are necessary to successfully complete a decking project with maximum efficiency.

5/32 High Speed Steel Taper Point Drill |

C7 Countersink with Stop Collar Taper Point Drill |

3/8 Wood Decking Plugs - many species available |

TRADITIONAL SCREWING METHOD:

HARDWOOD DECKING INSTALLATION TIPS

The first step is to pre-drill the decking boards before fastening them to the joists.

A good countersink bit is necessary to fasten the wood decking. Tapered bits are preferable. They provide a good “slip hole” through the high-density hardwood decking and a smaller tapered hole in the deck joist or framing. Drill slowly and remove the waste as you are drilling. This will keep the drill bit cooler and extend its usage. Regardless, always order extras.

Stainless steel deck screws are the only choice for fastening tropical hardwood decking.

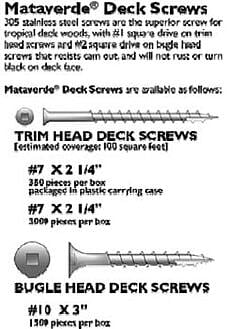

The deck fastener life must match the longevity of the decking material being used. Tropical hardwood decking will significantly outlast galvanized or coated deck screws. Mataverde® Deck Screws are the finest grade of 305 stainless steel to last longer. We recommend #7 trim head square drive decking screws for either ¾” or 1" thick decking material. These deck screws use a #1 square drive driver to reduce “cam out”.

The technique is just as important as the material used!

The countersink hole should be made slightly deeper into the deck board than the head of the screw. This allows the head of the screw to be set slightly below the surface of the deck board. When shrinkage occurs, the head will be flush or just below the surface of the decking. It is very important that the countersink bit must be held at a right angle to the wood deck surface. The drill bit will break if there is too much pressure at an angle prior to finishing the drilling operation. Remember, Mataverde® Hardwood Decking products are among the hardest decking woods on earth.

Wondering if our Concealed Deck Fastener is right for your project? Get a free sample and see for yourself.

Slow the speed of your drill down when you countersink.

Drill the hole to half depth, back the bit out, and clean the drilling waste prior to finishing the hole in the deck board. This will reduce breakage, extend the life of the bit and countersink as well, and provide a cleaner, more consistent hole in the deck board.

Go slow and steady when you install the deck screw into the decking.

This will prevent the screw from heating up excessively, distorting or breaking. If the deck screw starts to distort while driving it into the deck board, stop! Move on to the next deck screw. This will allow the decking screw to cool down before you stress it during the removal. Discard the deck screw and apply wax to the replacement deck screw threads. Drive the new deck screw slowly into the deck board.

What do you do if you break a deck screw?

Take a moment to determine what caused the breakage in the deck screw. Was the deck screw driven into the decking too quickly? Did it hit another fastener or building hardware below the deck surface? Vise-Grip pliers are the tool of choice for removing broken decking screws. Clamp the pliers on the head or what is left of the deck screw on the surface and twist the screw out. If the deck screw breaks below the surface, drill a slightly angled hole adjacent to the broken deck screw. It is best to use a 1/8” drill bit to perform this rather than a tapered countersink. Wax a new deck screw and slowly and carefully install it next to the broken deck screw.

RELATED:

Download THE Mataverde® Deck Fasteners Guidelines

Download Mataverde Decking Installation Guidelines

Mataverde® Screws andAccessories |

||

| Titebond Adhesive | 29 oz |  |

| 1" Deck Screws (Sub rail to Handrail) | 316/box | |

| 1-1/4" Deck Screws (Sub rail to Baluster) | 243/box | |

| 1-5/8" Deck Screws (Sub rail to Post) | 189/box | |

| 2-1/4" #7 Deck Screws 1 lb | 138/box | |

| 2-1/4" #7 Deck Screws 3 lb | 414/box | |

| 2-1/4" #7 Deck Screws 5 lb | 690/box | |

| 2-1/4" #7 Deck Screws 10 lb | 1380/box | |

| 3" x #10 Deck Screws | 1500/box | |

| Insert Bit | each | |

| 5/32 Countersink | each | |

| 5/32 Tapered Bit | each | |

| 3/8" Mataverde Decking Plugs | 100/bag | |

PRE-GROOVED HARDWOOD DECKING BOARDS

If you don’t have the inclination to cut slots into your decking boards, all Mataverde hardwood decking species are available as Pre-Grooved decking. This continuous groove makes decking installation much quicker whether you are installing your deck boards square or on a diagonal.

.jpg?width=311&height=224&name=Mataverde%20Euotec%20Deck%20Clip%20hidden%20fastener%20works%20great%20with%20pregrooved%20decking%20(800x575).jpg) |

|

HIDDEN DECK FASTENER METHOD

OPTIONS FOR HIDDEN FASTENERS FOR DECKING

THE MATAVERDE® EUROTEC® DECK CLIP

For a clean, unencumbered deck surface on a wood framed deck, many people prefer to use a hidden deck fastener. To achieve this look, the Mataverde Eurotec Hidden Deck Fastener is a great hidden fastening option for decking. To save lots of installation time and costs, you may want to use a Mataverde® Premium Hardwood Decking product that is “pre-grooved” or “slotted” on the sides.

Mataverde® Eurotec 100% Stainless Steel Deck Fastener |

|

Unlike other hidden deck fasteners, the Mataverde Eurotec Deck Clip and screws are made from 100% stainless steel for long life and holding power. Both are coated black for low visibility. The extra-long clip is ideal for aligning the decking, especially where the butt ends of two decking boards meet.

Rather than drilling and screwing through the face of the deck boards, the hidden fasteners are drilled and screwed on a 45-degree angle through the deck boards into the deck joists. The next pre-grooved deck board is then seated onto the deck fastener and the deck fastening process is repeated.

Because deck boards using this method are fastened on one side of the board only, we offer the following suggestions for best results and long-term satisfaction:

Want to see the best hidden deck fastener available?

Request a free hidden deck fastener sample today:

MATAVERDE CONCEALED DECK FASTENERS

CONCEALED DECK FASTENER INSTALLATION TIPS

- Always use 21 mm or 5/4 nominal thickness pre-grooved hardwood decking

- Always install a minimum of 36" above grade with adequate ventilation below your deck (3 sides open)

- Because it has a narrower face (and therefore less natural expansion and contraction as the wood 'seasons'), 21 mm x 4 or 5/4 x 4 hardwood decking works best for hidden fastening

- 21 mm x 6 or 5/4 x 6 decking (nominal sizes) may be used, but expect, and plan for, acclimation and natural shrinkage of these wider deck boards

The Mataverde Eurotec Hidden Deck Fastener Kit includes:

-

175 Stainless Steel Deck clips (black for lower visibility)

-

190 Stainless steel screws (black for lower visibility)

-

1 drill bit

-

1 driver bit

-

Covers approximately 100 sf of 5/4 x 6 decking area

The Mataverde Eurotec Hidden Deck Fastener Contractor Bucket includes:

-

525 Stainless Steel Deck clips (black for lower visibility)

-

570 Stainless steel screws (black for lower visibility)

-

2 drill bits

-

2 driver bits

-

Covers approximately 300 sf of 5/4 x 6 decking area

RELATED:

DOWNLOAD THE MATAVERDE EUROTEC DECK FASTENER BROCHURE

DOWNLOAD THE MATAVERDE DECKING INSTALLATION GUIDELINES

EJECTOR DECK SCREW METHOD

STAINLESS STEEL EJECTOR DECK SCREWS

A recent development in deck screw technology has created the “Ejector Screw”. This patented deck screw has a drill point, a coarse lower thread, a smooth upper shank, and a countersink head. The drill point eliminates the need for pre-drilling your deck boards. The coarse thread drives the screw home. The smooth upper shank ejects the drilling waste. The countersink head eliminates the need for countersinking each deck hole. This amazing new deck screw performs all four steps in one smooth motion.

Whether you are a homeowner or a construction professional, the Ejector Screw will save you time and wear and tear on your body every time you install deck boards.

In addition to reducing the stress, strain, and fatigue on your shoulders, arms, knees, and lower back muscles while installing deck boards, the Speed Driver can be used to accurately apply over 1,000 deck screws per hour. That makes it about five times faster than conventional drilling and deck screwing techniques.

LABOR-SAVING DECK INSTALLATION PRODUCTS

EJECTOR DECK SCREW METHOD

|

|

||

|

|

|

|

|

||

| Ejector Screw Speed Driver Gun (*includes 10 bits) | each |

| Ejector Screw Ultra Driver Gun (*includes 10 bits) | each |

| 2" Ejector Deck Screws | 1800/box |

| 2" Ejector Deck Screws | 150/coil |

| 2-1/2" Ejector Deck Screws | 900/box |

| 2-1/2" Ejector Deck Screws | 150/coil |

| 3" Ejector Deck Screws | 900/box |

| 3" Ejector Deck Screws | 150/coil |

| Ejector Screw Square Drive Bits | 10/C |

DOWNLOAD THE MATAVERDE DECK FASTENERS GUIDELINES

DOWNLOAD THE MATAVERDE DECKING INSTALLATION GUIDELINES

Need a little deck design inspiration? Looking for some great deck ideas?

Download the "Deck design Ideas Book" for 61 pages and over 150 real deck projects and ideas.

RELATED:

Illustration of the Mataverde® Eurotec Deck Clip installation

Illustration of the Mataverde® Eurotec Deck Clip installation